Over the next few weeks, I will be working with Matt (v8rx7guy) to prep the RX-7 for the engine/transmission swap (date of swap TBD). If you missed the project introduction post, be sure to check it out here.

This weekend, we spent a few hours making some progress on the preparation. One of the best things to do before starting a project car is to verify the functionality of the stock components. The previous owner mentioned that before the rotary blew up, he thought that nearly everything on the car worked. We wanted to confirm this before any wiring was removed or modified.

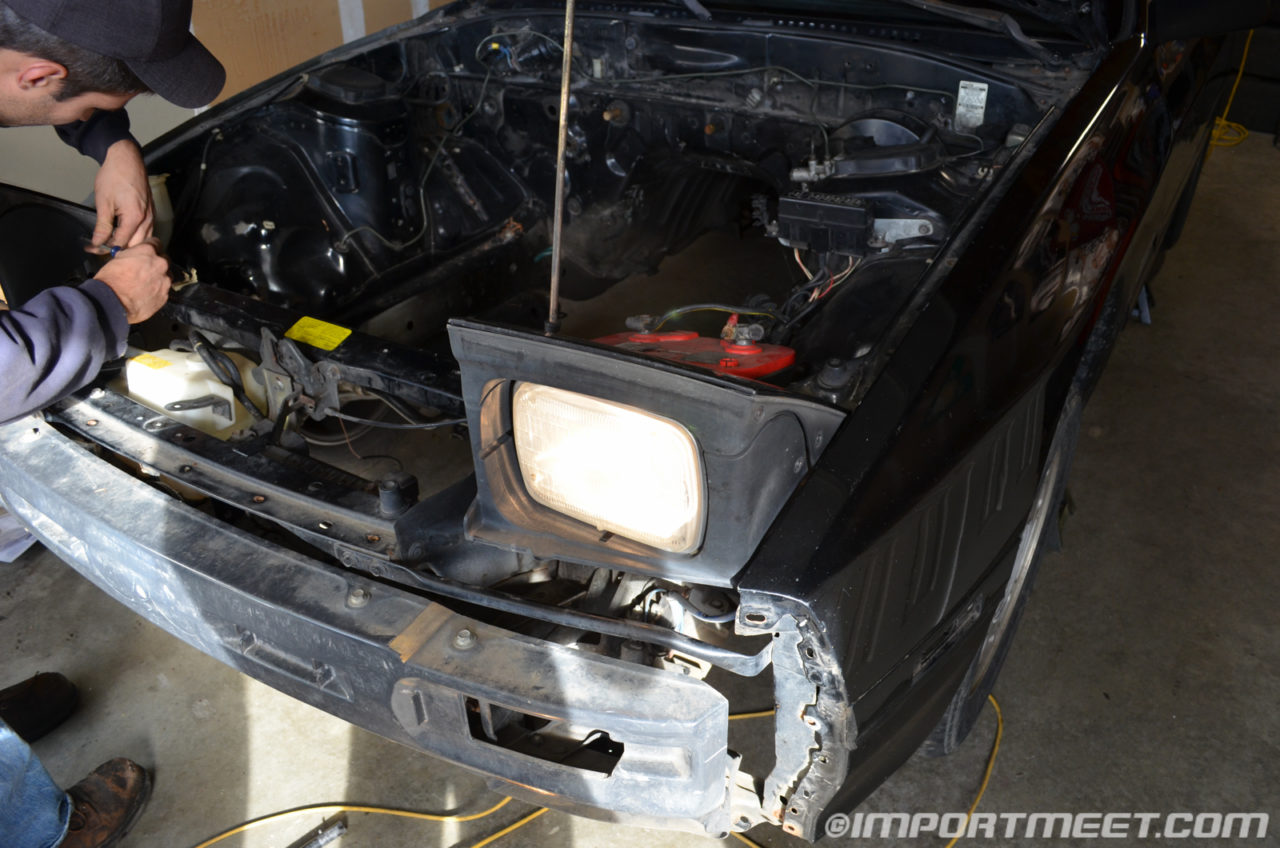

The shell didn’t come with a battery so one was borrowed from another car to test the electrical systems. All of the lights, dash controls, and motorized parts worked with the exception of the passenger headlight and sunroof. The passenger headlight rod that goes from the motor to the headlight assembly had popped off and was jammed into the bumper support. When I bought the shell, I was aware that a previous owner had ripped the front bumper off on this side so it wasn’t a huge surprise.

The shell didn’t come with a battery so one was borrowed from another car to test the electrical systems. All of the lights, dash controls, and motorized parts worked with the exception of the passenger headlight and sunroof. The passenger headlight rod that goes from the motor to the headlight assembly had popped off and was jammed into the bumper support. When I bought the shell, I was aware that a previous owner had ripped the front bumper off on this side so it wasn’t a huge surprise.

To the fix the headlight, the prop rod was removed and reattached. Once in the proper position, the motor moved the headlight but it was still rubbing on a brace that connects the inner fender to the core support. It was slightly bent (from the accident) and will need to be replaced in the near future. The sunroof will most likely be removed and filled with a fiberglass or a carbon fiber plug so its functionality wasn’t critical.

The next step was to remove the remaining engine and electrical harnesses to the front of the car. We knew that most of the Mazda wiring isn’t necessary so the plan is to go through and remove all unneeded wires. Rumors on various forums state that nearly 15 lbs can be removed in excess wiring alone! Each of the key connections were labeled and will be compared to wiring schematics to find out exactly which wires are not necessary.

The next step was to remove the remaining engine and electrical harnesses to the front of the car. We knew that most of the Mazda wiring isn’t necessary so the plan is to go through and remove all unneeded wires. Rumors on various forums state that nearly 15 lbs can be removed in excess wiring alone! Each of the key connections were labeled and will be compared to wiring schematics to find out exactly which wires are not necessary.

As you can see, the engine bay had a thick layer of grease on most surfaces along with zip tie holders and clips that will not be needed. These were all removed along with the clutch master cylinder which will be upgraded for the swap.

Lastly, the engine bay was sprayed down with de-greaser to clean it. Below you can see comparison shots of the before and after cleaning. We still plan on spraying the bay down with a Simple Green and water mixture to get any remaining dirt and grease off next week.

Lastly, the engine bay was sprayed down with de-greaser to clean it. Below you can see comparison shots of the before and after cleaning. We still plan on spraying the bay down with a Simple Green and water mixture to get any remaining dirt and grease off next week.

Before:

All in all, it was a great weekend with tons of progress made. Next week, we plan on cutting small pieces off the core support sheet metal to make room for a radiator and also remove the dash to get the remaining wires through the firewall. Then the FUN task of rewiring the harnesses will begin. Keep checking back as updates will continue to be posted in the coming weeks!

All in all, it was a great weekend with tons of progress made. Next week, we plan on cutting small pieces off the core support sheet metal to make room for a radiator and also remove the dash to get the remaining wires through the firewall. Then the FUN task of rewiring the harnesses will begin. Keep checking back as updates will continue to be posted in the coming weeks!

Previous posts about Project FC RX-7:

7 Comments

looking good. Have you decided on any potential swaps or leaning toward any particular swap? So far Im impressed. Good job. Cant wait to see it done.

So fresh and so clean, clean!

good to see some headway on this project. keep it up matt!

All of the FCs I have seen have always had a bare driver side frame rail from the rotary leaking. If you are going to keep the heater you should reroute the heater lines behind the dash when you have it out.

The pick n pull in Arlington has two FCs, one S4 and on S5. There isn’t much left on the S5 but it does still have the fenders and they are in excellent condition though they are white. The S4 was also white and more complete.

Thanks for the heads up. The S4 one wasn’t a Turbo II was it?

Nope they were both N/a. It is hard to find a Turbo II in a junkyard.